The Internet of Things (IoT) is transforming predictive maintenance by tracking equipment in real-time through the use of IoT. IoT sensors communicate with the cloud, sensing anomalies in devices prior to failure, decreasing downtime and maintenance expenses. This advance warning system optimizes efficiency, prolongs asset longevity, and guarantees enhanced safety as well. IoT predictive maintenance is transforming industries by delivering smart maintenance solutions, data-based insights that enable companies to predict issues and achieve maximum performance.

Table of Content

What Is Predictive Maintenance and Why Does It Matter?

Predictive maintenance is a preventive approach that employs data and intelligent technology to identify when equipment is likely to fail—before it happens. IoT Predictive maintenance allows companies to prevent expensive breakdowns, minimize downtime, and make best use of maintenance against reactive or scheduled methods.

The Role of IoT in Transforming Traditional Maintenance Models

The Internet of Things has revolutionized maintenance by causing equipment and devices to “speak” with each other through sensors and networks. Rather than having to make educated estimations about when a machine will break down, IoT enables real-time monitoring of performance and to be alerted when something is wrong.

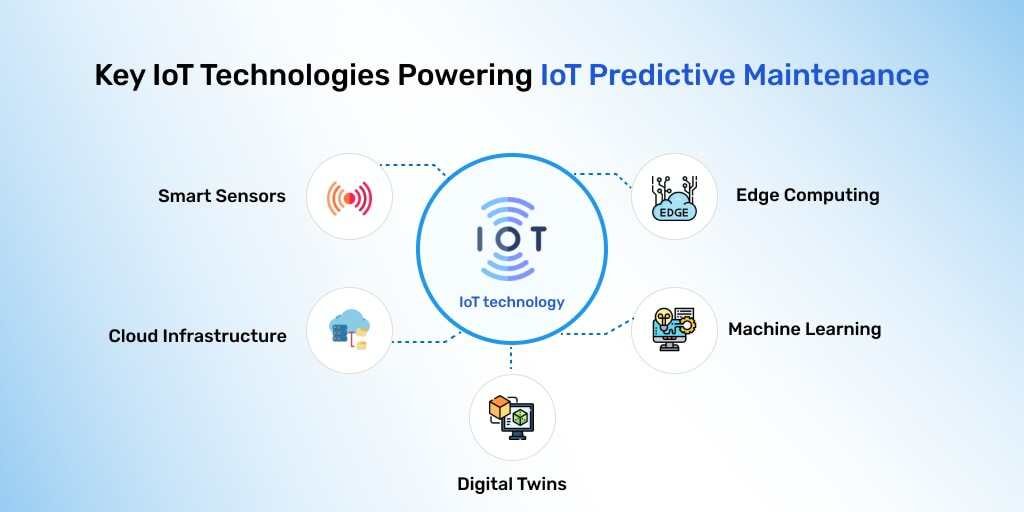

Key IoT Technologies Powering IoT Predictive Maintenance

- Smart Sensors: Smart sensors track equipment conditions such as vibration, pressure, and temperature in real-time. They give advance warnings of failure, enabling organizations to respond before they occur.

- Edge Computing: Edge computing processes sensor data near the source, enabling instant decisions. Latency is minimized and response is quicker to equipment problems without the use of the cloud. Data privacy is also improved by restricting the data transferred over networks.

- Cloud Infrastructure: Cloud platforms store and analyze massive volumes of sensor data. They offer remote access to insights and support long-term trend analysis for better maintenance planning. Cloud scalability ensures businesses can handle growing data as IoT networks expand.

- Machine Learning: Machine learning identifies patterns in historical data to predict future equipment failures. It helps shift from reactive to proactive maintenance with higher accuracy over time. Continuous model training improves prediction reliability as new data flows in.

- Digital Twins: Digital twins are computerized copies of tangible assets. They model equipment performance and stress conditions, making it possible for teams to identify and forestall issues before they arise. Such dynamic modeling also helps optimize operational parameters and maintenance schedules.

Benefits of IoT Predictive Maintenance for Businesses

Reduced Downtime:

IoT sensors aid early detection of problems, enabling companies to plan maintenance ahead of time before potential failures take place. This reduces downtime and maintains operations in motion. Proactive actions further enhance customer satisfaction through consistent delivery of products and services.

Cost Savings

By catching problems in advance, companies avoid expensive emergency repairs and reduce unnecessary routine checks—saving money over time. This efficient resource use also lowers labor costs and optimizes inventory management for spare parts.

Extended Equipment Life

Predictive analytics in IoT maintenance ensures the equipment is maintained when required, which maximizes the life cycle of expensive machinery and minimizes capital outlays. It reduces replacement needs, which allows for improved IoT asset management and budgeting.

Real-time monitoring

Real-time monitoring avoids dangerous failures, ensuring companies provide safer workplaces and safeguard people and assets. Real-time monitoring also assists with regulatory compliance by tracking maintenance and safety procedures.

Greater ROI

With better performance equipment and fewer interruptions, businesses realize optimal return on investment and superior overall operational efficiency. Better productivity and lower operational risks lead to good financial performance.

Challenges in Implementing IoT Predictive Maintenance

- Initial Costs: Installation of IoT-based maintenance systems involves initial investment in sensors, software, and professional labor, which might prove difficult for smaller companies.

- Integration Issues: Most of these businesses continue employing legacy systems that are not readily compatible with contemporary IoT platforms, leading to deployment delays and data streams.

- Data Overload: With thousands of data points streaming in, it can be overwhelming without the right tools or expertise to filter and interpret the information.

- Cybersecurity Risks: Connected devices increase the attack surface. If not secured properly, they can expose critical systems to data breaches and cyber threats.

- Skill Gaps: Maintenance teams need training to manage IoT tools, analyze real-time data, and respond to predictive analytics in IoT alerts effectively.

Future Trends: Where Is IoT-Driven Maintenance Headed?

- AI-Enhanced Platforms: AI models will get even better at predicting failures, helping companies act before problems become critical—improving accuracy and confidence. This will lead to smart maintenance solutions decision-making and more efficient allocation of maintenance resources.

- 5G-Powered IoT: 5G connectivity enables real-time data exchange from remote or mobile equipment, making monitoring faster and more seamless. It also supports the deployment of more connected devices across large, complex infrastructures.

- Autonomous Maintenance: Machines will soon perform self-diagnostics and alert technicians—or even self-correct—without human input, reducing downtime further. This automation will enhance safety and free up human workers for higher-value tasks.

- Sustainability Focus: With smarter energy use and less waste, predictive analytics in IoT maintenance helps businesses lower carbon emissions and meet environmental goals. It promotes longer IoT asset management lifecycles and reduces the environmental impact of manufacturing and operations.

Real-World Use Cases of IoT in Predictive Maintenance

Manufacturing

IoT sensors are implemented in manufacturing plants to track the health of equipment, preventing breakdowns and maintaining production lines. Systematic monitoring allows for maintenance at the best times, preventing downtime and boosting productivity.

Logistics

Fleet managers use IoT trackers in the vehicles to detect engine or battery malfunctions prior to happening, reducing breakdowns on the road. Real-time data also optimizes routes and fuel consumption, lowering overall operating costs.

Energy Sector

Utilities install smart sensors on turbines and transformers to detect overheating or vibration faults before they fail, with efficient power delivery guaranteed. Predictive notifications facilitate timely maintenance to avoid expensive outages and increase asset lifespan.

Healthcare

Hospitals utilize IoT to monitor the well-being of MRI machines, ventilators, and other life-support equipment—saving time and enhancing patient care. Reliability-driven equipment is spurred by proactive maintenance and enables vital healthcare procedures.

Oil & Gas

IoT sensors track pressure and flow through pipes to detect anomalies, preventing leaks, environmental dangers, and unnecessary repairs. Continuous data processing enables regulatory compliance and safety feature optimization.

Why Choose Hutech Solutions for IoT-Driven Maintenance

- Seamless Integration: We help you connect smart sensors with your current systems—no need to start from scratch.

- Real-Time Dashboards: Our cloud-native dashboards give you full visibility into your asset health and maintenance needs anytime, anywhere.

- AI-Powered Insights: Get ahead of failures with AI-driven fault detection that learns from your data and improves over time.

- Enterprise-Grade Security: Hutech Solutions ensures your IoT ecosystem is safe with robust encryption, secure architecture, and compliance-ready systems.

- Tangible ROI: From fewer breakdowns to improved resource planning, we are committed to providing measurable business results you can monitor and grow.

Conclusion

Embracing IoT predictive maintenance revolutionizes business operations by reducing risk, saving cost, and achieving highest system availability. Intelligent process guarantees smooth and error-free functioning of the machine. Collaborate with professionals such as Hutech Solutions to future-proof your infrastructure with enhanced efficiency and competitiveness. Stay ahead of today’s fast-paced market with IoT maintenance strategies that deliver value in the long run and operational excellence.

Ready to Advance your Digital Transformation?Get in touch with us.

Discover why Hutech is the right partner for your business.

MAIL US AT

sales@hutechsolutions.com

CONTACT NUMBER

+91 90351 80487

CHAT VIA WHATSAPP

+91 90351 80487

Humantech Solutions India Pvt. Ltd 163, 1st Floor, 9th Main Rd, Sector 6, HSR Layout, Bengaluru, Karnataka 560102